EXCELLENCE IS THE STARTING POINT

PRODUCTS

PRODUCTS

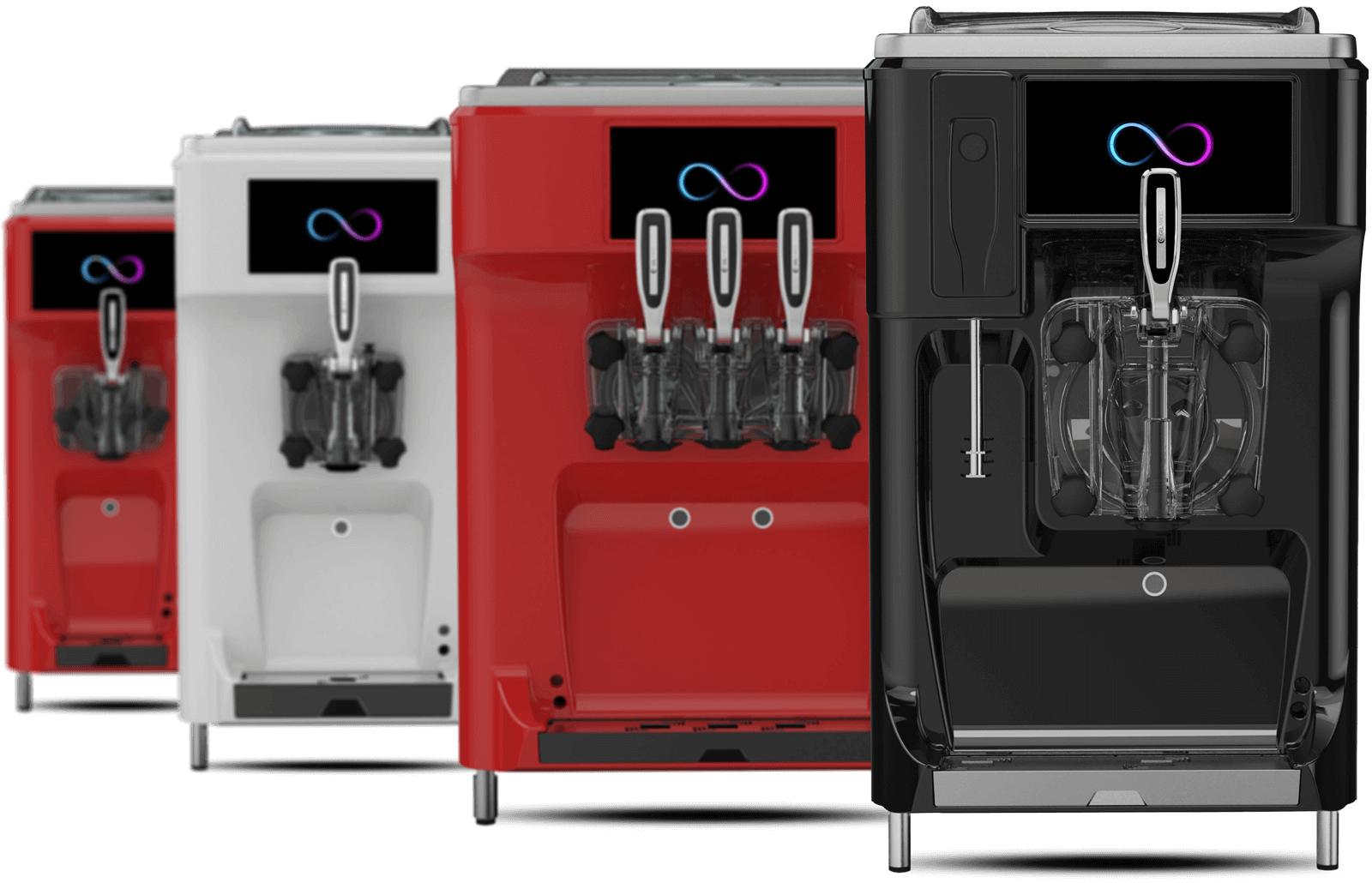

Not just gelato and ice-cream, but also frozen yoghurt, milkshakes, desserts and chilled desserts

Express blending and freezing

GTECH

GTECH

We offer qualified resources to guarantee the best possible use of our machines

News

GEL MATIC AT SIGEP 2024

We are ready and thrilled for SIGEP 2024. Come to see us, we will be delighted to welcome you.

6 November 2023

GEL MATIC AT HOST 2023

We’ll attend the 43rd edition of Host, International Hospitality Exhibition.

26 September 2023

GEL MATIC AT SIGEP 2023

We’ll attend the 44th edition of Sigep, International Trade Show of Artisan Gelato, Pastry, Bakery and the Coffee World.

7 November 2022